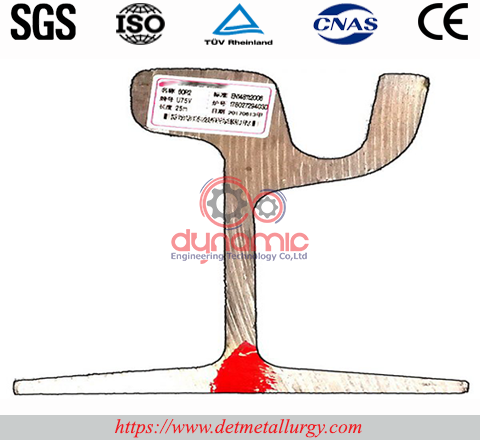

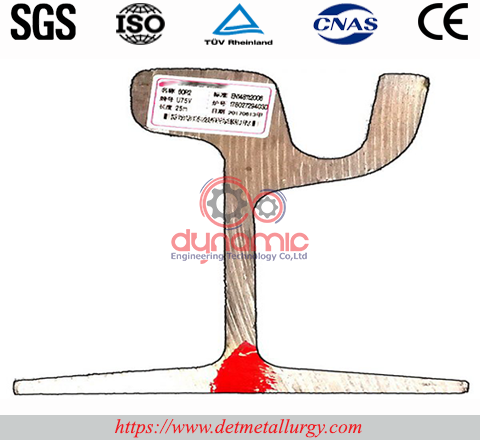

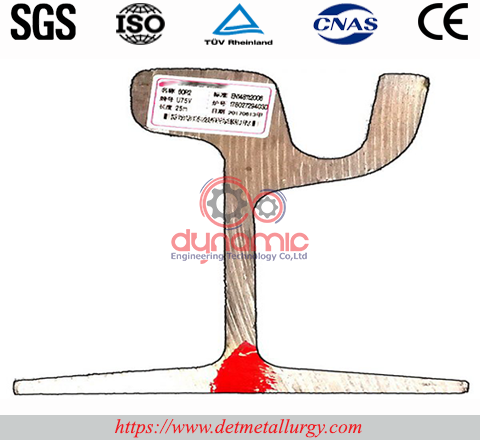

Grooved Steel Rail or Channel Rail for Urban Trams

grooved-rails

GroovedSteelRail-1

GroovedSteelRail-2

GroovedSteelRail-3

GroovedSteelRail-4

Channel rail is used for light railway line or trams, the top of the rail track is fixed to match the ground surface that pedestrian can walk and cross. The below are the detailed Specification of the grooved steel rail or channel rail.

| General Product Specification & Terms | ||||||

| Standard | YB/T 4653 | Grade/Material | U71Mn,U75V | |||

| Model Number | 59R2,60R2 | Weight | Customized | |||

| Length | 6m-25m | Packing | Bundling | |||

| Mfg. Technique | Hot Rolled | Application | channel rail | |||

| Country of Origin | 200km/h | Incoterms | EXW, FCA, FOB, CIF, CNF | |||

| Train Speed | 200km/h | MOQ | 500tons | |||

| Fastening | Joint bar, Rail anchor, spike & bolt, and other parts are provided on demand. | |||||

| Processing | Drill hole according to your requirement |

|||||

| Channel Rail Detailed Specification |

||||||

| Classification Grades | Chemical Composition (mass fraction) % | |||||

| C | Si | Mn | V | p | S | |

| U71Mn | 0.65-0.76 | 0.15-0.58 | 0.70-1.20 | — | ≤0.030 | ≤0.025 |

| U75V | 0.71-0.80 | 0.50-0.80 | 0.75-1.05 | 0.04-0.12 | ≤0.030 | ≤0.025 |

| Physical Properties (Hot-rolled rail tensile strength and elongation after break) | ||||||

| Classification Grades | Tensile Strength Rm/MPa | Elongation after break A/% | ||||

| U71Mn | ≥880 | ≥10 | ||||

| U75V | ≥980 | ≥10 | ||||

| Remarks: In the sample test of hot saw, the allowable elongation after fracture is 1% lower than the specified value (absolute value). |

||||||

| Hot finished rail tensile strength and elongation after break | ||||||

| Grade | Tensile Strength Rm/MPa | elongation after break A/% | ||||

| U71Mn | ≥1080 | ≥10 | ||||

| U75V | ≥1180 | ≥10 | ||||